Robotics automation is reshaping industries across the globe, bringing profound transformations in manufacturing, healthcare, logistics, agriculture, and more. As advancements in artificial intelligence (AI), machine learning (ML), and robotics continue to progress, automation technologies are increasingly becoming more integrated into daily operations. These robots are not only performing repetitive tasks but also adapting to complex environments, learning from data, and working alongside human employees to enhance productivity and efficiency.

In this article, we will explore the numerous ways in which robotics automation is revolutionizing industries, its benefits, challenges, and potential future developments.

Key Takeaways

- Robotics automation is revolutionizing industries such as manufacturing, healthcare, logistics, agriculture, retail, and construction.

- The benefits include improved productivity, precision, safety, and cost reductions.

- Robotics complement human workers by taking on repetitive, dangerous, or high-precision tasks.

- Despite challenges like labor displacement and high initial costs, the overall impact of robotics automation is overwhelmingly positive.

- As AI and machine learning continue to advance, the future of robotics automation holds immense potential for even more profound transformations across sectors.

The Rise of Robotics Automation

Robotics automation has been evolving for decades, but in recent years, it has reached a point where it can be adopted at scale in various industries. Automation refers to the use of machines and robots to perform tasks that traditionally required human intervention. Robotics automation is a subset of automation that involves machines designed to execute specific tasks autonomously or semi-autonomously.

From assembly lines in manufacturing plants to high-tech surgery robots, robotics automation is everywhere. The key driving forces behind this rise are:

- Advancements in Technology: AI, sensors, and machine learning algorithms have made robots smarter and more capable of performing complex tasks.

- Cost Reduction: Over time, automation has reduced operational costs by increasing efficiency and minimizing human error. While the initial investment can be high, the long-term return on investment (ROI) is substantial.

- Labor Shortages: Many industries face a shortage of skilled workers, especially in fields that require manual labor. Robotics automation can bridge this gap by performing tasks that would otherwise go unfilled.

- Consumer Demands: The need for faster production and delivery has pushed industries to adopt automation. Robotics can work 24/7 without the need for breaks or downtime.

How Robotics Automation is Revolutionizing Industries

1. Manufacturing: Efficiency and Precision

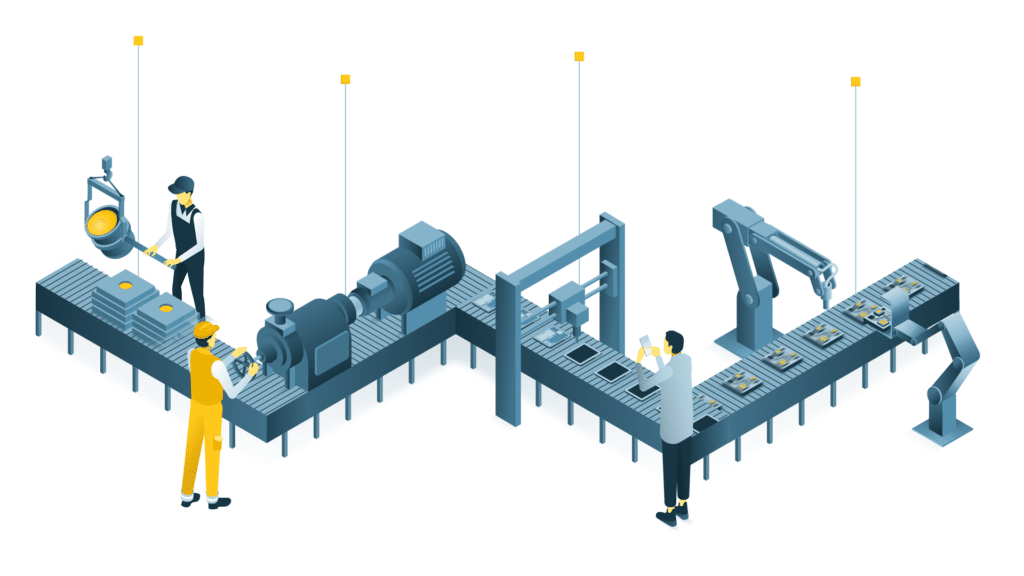

Manufacturing was one of the first sectors to adopt robotics automation. Robotics systems in manufacturing can perform a wide variety of tasks such as welding, assembly, painting, material handling, and quality inspection.

Benefits:

- Improved Productivity: Robots can work round-the-clock, increasing the overall output of factories.

- Precision and Consistency: Robots can execute tasks with high precision, ensuring consistent product quality and reducing waste.

- Safety: Robots can perform dangerous tasks such as handling hazardous materials or working in high-risk environments, keeping human workers safe.

- Flexibility: Modern robotic systems can be programmed to perform multiple tasks, making them more adaptable to changes in production lines.

With robotics automation, factories are not just more efficient but also safer and more adaptable to changing demands. For example, the automotive industry has seen massive growth in the use of robotic arms for tasks such as welding, assembly, and packaging.

2. Healthcare: Precision Surgery and Care

In healthcare, robotics automation has paved the way for life-saving innovations. Surgical robots, such as the da Vinci Surgical System, are now used for minimally invasive surgeries, which reduce recovery times, lower the risk of infection, and enhance precision. Additionally, robots are being utilized for rehabilitation and elderly care.

Benefits:

- Improved Surgical Outcomes: Robotic systems enable surgeons to perform delicate procedures with greater accuracy and control.

- Remote Surgery: With advancements in teleoperation, surgeons can now conduct surgeries remotely, providing access to healthcare in remote areas.

- Assistive Robots: Robots are used in elderly care to assist with tasks such as medication reminders, mobility assistance, and monitoring patient health.

- 24/7 Care: Robots can monitor patients around the clock, providing continuous support without tiring or requiring rest.

The integration of robots in surgery also allows for faster procedures with fewer complications, ultimately improving patient outcomes.

3. Logistics and Warehousing: Streamlining Supply Chains

The logistics and warehousing industry is experiencing a massive shift due to robotics automation. Automated guided vehicles (AGVs), drones, and sorting robots are making warehouses smarter and more efficient. Companies like Amazon and Walmart have already adopted robotic systems for inventory management, picking, packing, and sorting items.

Benefits:

- Faster Operations: Robots can navigate warehouses efficiently, reducing the time it takes to locate, pick, and pack items.

- Reduced Human Error: Automation reduces mistakes, such as incorrect order fulfillment, which often leads to customer dissatisfaction.

- Inventory Management: Robotics systems can automatically track and update stock levels, ensuring warehouses are always stocked and operations run smoothly.

- Cost Reduction: By automating routine tasks, companies save on labor costs, while increasing overall efficiency.

For instance, Amazon’s Kiva robots autonomously transport shelves of products to human workers, who then pick the items. This system has drastically cut down order processing time and increased warehouse efficiency.

4. Agriculture: Smart Farming for Better Yields

Robotics automation is also making waves in the agricultural sector. Autonomous tractors, drones, and harvesters are being deployed to improve the efficiency of farming. These robots help monitor crop health, perform precision farming, and increase yields while minimizing resource use.

Benefits:

- Precision Agriculture: Robots equipped with sensors and cameras can detect pests, diseases, and areas needing irrigation, allowing for targeted interventions that conserve resources.

- Increased Efficiency: Automated machinery can work longer hours and complete tasks more quickly than human workers, improving harvests and productivity.

- Labor Shortages: The agriculture industry often faces labor shortages, especially during peak seasons. Robotics automation fills this gap by handling repetitive tasks like harvesting or planting.

- Sustainability: With the help of robotics, farmers can optimize the use of water, fertilizers, and pesticides, leading to more sustainable farming practices.

For example, the development of autonomous tractors by companies like John Deere is revolutionizing the way fields are plowed, planted, and harvested, allowing for precision and efficiency.

5. Retail: Enhancing the Customer Experience

Retailers are using robotics automation in various ways, from automated checkout systems to customer service robots. Self-checkout systems, powered by robotics, have become commonplace in stores, reducing wait times and improving customer experience.

Benefits:

- Improved Customer Service: Robots can answer customer queries, guide them through stores, or even assist in locating items.

- Efficient Inventory Management: Robots can monitor stock levels and ensure shelves are always replenished, optimizing inventory and reducing human labor.

- Enhanced Shopping Experience: With robots handling menial tasks, employees can focus on more personalized services for customers.

- Cost-Effective Operations: Retailers reduce costs related to human resources and improve efficiency with automated systems in place.

For example, Lowe’s and Walmart have deployed robots to scan shelves for out-of-stock items, improving inventory management and ensuring customers can find the products they need.

6. Construction: Building Safer and Smarter

In the construction industry, robotics automation is enhancing safety, precision, and productivity. Robots are being used for tasks like bricklaying, concrete pouring, and even the construction of entire buildings.

Benefits:

- Increased Safety: Construction is a high-risk industry, but robotics can take over dangerous tasks such as lifting heavy materials or working in hazardous conditions.

- Precision and Speed: Robots can carry out repetitive tasks with high accuracy, reducing the likelihood of human error and accelerating the construction process.

- Cost-Effective: By using robots, construction companies can reduce labor costs while improving project timelines.

One example is the use of robots like the SAM (Semi-Automated Mason) to lay bricks. This robotic system can lay bricks faster than human workers, improving the efficiency and cost-effectiveness of construction projects.

Manufacturing: The Backbone of Robotics Automation

Robotics automation has had its greatest impact in manufacturing, an industry that has historically relied heavily on manual labor. With the rise of Industry 4.0, a term used to describe the ongoing revolution in manufacturing technology through the internet of things (IoT), cyber-physical systems, and robotics, manufacturers are now achieving unprecedented levels of efficiency.

Industrial Robots in Manufacturing: Industrial robots are equipped with powerful arms that can perform a variety of tasks such as welding, painting, assembly, and packing. These robots use sensors and cameras to execute their tasks with extreme accuracy, improving quality control in the manufacturing process.

Collaborative Robots (Cobots): A key development in this area is the advent of cobots (collaborative robots), which are designed to work alongside human workers safely. Cobots can perform tasks such as lifting heavy objects, assembling parts, or even conducting quality checks on the assembly line. Unlike traditional industrial robots, cobots are easier to program and can be reconfigured to handle different tasks, making them particularly valuable in small and medium-sized businesses that cannot afford large-scale automation systems.

Case Study:

- Tesla: Tesla has long been a leader in automating its manufacturing processes. In their electric vehicle production line, robots are used for tasks ranging from painting car bodies to welding chassis parts. Tesla’s Gigafactories are a prime example of how automation is used to scale up production while maintaining a high degree of quality control.

Healthcare: The Role of Robotics Automation in Medical Procedures

Robotics automation is playing an increasingly prominent role in healthcare. In fields like surgery, rehabilitation, and patient care, robotics has enabled more precise, faster, and safer medical procedures.

Surgical Robots: One of the most well-known examples of robotics in healthcare is the da Vinci Surgical System. This robotic system allows surgeons to perform minimally invasive surgeries with high precision using small incisions. The system provides magnified 3D images, enhancing the surgeon’s view and making complex surgeries safer and less invasive.

Robotic-Assisted Rehabilitation: In physical therapy, rehabilitation robots are used to help patients recover mobility after strokes, accidents, or surgeries. These robots can assist in repetitive movement exercises, a key part of rehabilitation, enabling faster and more accurate recovery.

Case Study:

- Intuitive Surgical: This company’s da Vinci Surgical System has transformed various fields of surgery, including urology, gynecology, and cardiothoracic procedures. The system’s ability to execute complex, highly accurate movements with smaller incisions has significantly reduced patient recovery times.

Logistics and Warehousing: Robotics Driving Supply Chain Innovation

Robotics automation is significantly transforming logistics and warehousing. With the rise of e-commerce, companies need to meet consumer demands for faster shipping and on-time deliveries, making automation more critical than ever.

Automated Guided Vehicles (AGVs) and Drones: In warehouses, AGVs are used to transport goods, and drones are being developed to deliver packages. These robots reduce the need for human workers to move heavy goods, making the supply chain process more efficient. AGVs can work in environments like Amazon’s fulfillment centers, where they autonomously navigate, carry, and drop off goods.

Smart Sorting and Packaging: Robots are now capable of sorting and packaging goods with minimal human intervention. These systems can identify and pick products from shelves, reducing the risk of human error and speeding up the fulfillment process.

Case Study:

- Amazon: Amazon has pioneered the use of robotic systems in its warehouses. Its use of Kiva robots to transport shelves of goods to human workers has dramatically increased the efficiency of its warehouse operations. By automating the movement of items, Amazon has reduced the time it takes to process and ship orders.

Agriculture: Robotics in Farming for Precision and Efficiency

Agriculture is another field where robotics automation is helping to increase productivity while reducing environmental impact. By adopting robots, farmers can monitor crops, improve yields, and even reduce the use of pesticides and fertilizers, leading to more sustainable farming practices.

Autonomous Harvesters and Tractors: Autonomous machines such as self-driving tractors and harvesters are able to work long hours without needing breaks or human supervision. These machines can perform tasks such as tilling soil, planting seeds, and harvesting crops more efficiently than human laborers.

Precision Agriculture: Precision farming involves using robotics and sensors to optimize resource usage. Drones equipped with cameras and sensors are used to monitor crop health, detect pest problems, and assess soil quality. This allows farmers to apply fertilizers, pesticides, and water only when and where they are needed, reducing waste and environmental impact.

Case Study:

- John Deere: John Deere’s autonomous tractors and smart farming equipment are reshaping agriculture. The company’s See & Spray technology uses computer vision and machine learning to identify and spray only the weeds, significantly reducing the amount of herbicide used.

Retail: Robotics Automation Enhancing Customer Experience and Operations

In the retail industry, robotics automation is making shopping faster, more convenient, and safer. From in-store robots to automated checkouts, robotics is reshaping the way consumers interact with businesses.

Self-Checkout and Inventory Robots: Retail stores are deploying self-checkout systems that allow customers to scan and pay for items without the need for a cashier. Additionally, robots like LocusBots are used for inventory management. These robots move around the store, scanning shelves to ensure that products are stocked and organized.

Robotic Customer Service: Robots are also being used as interactive kiosks or assistants that can guide customers, answer questions, and even check them out at the point of sale. These systems can reduce wait times and provide personalized recommendations based on customer data.

Case Study:

- Walmart: Walmart has invested in robotic systems for both inventory management and customer service. Its use of Shelf-scanning robots allows employees to focus on higher-value tasks like customer service and restocking shelves, rather than spending time searching for out-of-stock items.

Construction: Robotics to Improve Safety and Efficiency

The construction industry is another sector undergoing a significant transformation due to robotics automation. Construction robots are being used to reduce human labor, perform dangerous tasks, and improve accuracy in building projects.

Robots for Bricklaying and Concrete Pouring: Robots such as the SAM (Semi-Automated Mason) are revolutionizing construction. SAM can lay bricks 3-5 times faster than a human mason, speeding up the construction process and lowering labor costs. Robots are also used for tasks like concrete pouring and even 3D printing of building materials.

Drones in Construction: Drones are widely used in construction sites to survey land, monitor building progress, and inspect infrastructure. These drones provide real-time data that helps contractors make more informed decisions and improve project management.

Case Study:

- Apis Cor: This company has developed a mobile 3D printing robot that can print entire buildings in a fraction of the time it takes to build them traditionally. The robot is capable of constructing homes using concrete, which could help reduce construction costs, especially in developing regions.

Challenges of Robotics Automation

While robotics automation offers immense benefits, there are several challenges that industries face when adopting these technologies:

- High Initial Costs: One of the most significant barriers to entry for many businesses is the high upfront cost of purchasing and installing robotic systems. However, as technology improves, the cost of robots is expected to decrease over time.

- Job Displacement: While automation has the potential to create new jobs, it also poses a risk of job displacement, particularly in industries that rely heavily on manual labor. Workers may need retraining to take on new roles that complement automation.

- Integration Complexity: Integrating new robotic systems into existing workflows can be complex. Companies may need to upgrade their infrastructure and train their workforce to use new technologies, which can be time-consuming and expensive.

- Ethical Concerns: The rise of robots in industries raises concerns about privacy, job security, and ethics. As robots take on more tasks, society must address questions about how to balance automation with human employment.

Future Trends in Robotics Automation

The future of robotics automation is bright, with several exciting trends shaping the industry:

- Artificial Intelligence Integration: AI will continue to improve robotics, allowing robots to learn from their environments, adapt to changes, and make decisions autonomously. This will lead to robots becoming more versatile and capable of handling increasingly complex tasks.

- Robotics as a Service (RaaS): With RaaS, businesses can lease robots instead of buying them outright, making automation more accessible to small and medium-sized enterprises.

- 5G and Robotics: The rollout of 5G Networks will enable faster communication between robots, sensors, and devices, leading to more efficient and reliable robotic systems, particularly in industries such as logistics and healthcare.

- Collaborative Robots: Future robots will work even more closely with human employees. These robots will be equipped with sensors and AI to ensure they can operate safely in shared workspaces with humans.

Also Read : What Is Robotics Engineering And How Does It Shape The Future?

Conclusion

Robotics automation is no longer just a futuristic concept but a present-day reality that is transforming industries across the world. By improving productivity, reducing costs, enhancing safety, and providing more precise operations, robotics automation is enhancing the way industries operate. While challenges such as initial investment costs, job displacement, and technical barriers remain, the benefits are undeniable. As technology continues to advance, robotics automation will undoubtedly play a crucial role in shaping the future of industries and revolutionizing the way we work and live.

FAQs

- What is robotics automation?

- Robotics automation refers to the use of robots or automated systems to perform tasks that were traditionally done by humans. These tasks can range from simple repetitive tasks to complex operations in various industries.

- What industries are benefiting from robotics automation?

- Industries such as manufacturing, healthcare, logistics, agriculture, retail, and construction are significantly benefiting from robotics automation by improving efficiency, reducing costs, and increasing safety.

- Are robots replacing human jobs?

- While robots can perform certain tasks more efficiently than humans, they are primarily designed to complement human workers. Many jobs involve collaboration between humans and robots, with robots handling repetitive or hazardous tasks.

- How does robotics automation improve productivity?

- Robotics automation increases productivity by performing tasks faster and more accurately than humans, working 24/7 without breaks, and reducing human error.

- What are the risks of robotics automation?

- Some risks include the potential for job displacement, high initial investment costs, cybersecurity vulnerabilities, and challenges with the integration of new technologies into existing workflows.

- What is the future of robotics automation?

- The future of robotics automation is promising, with robots becoming more intelligent, autonomous, and versatile. Expect to see more robots working alongside humans in industries like healthcare, manufacturing, and customer service.

- How does robotics automation improve safety?

- Robotics automation improves safety by taking over hazardous tasks that could be dangerous for human workers, such as handling toxic materials, working in high-risk environments, or performing complex surgeries.